MINIATUREFOLDING

MACHINES

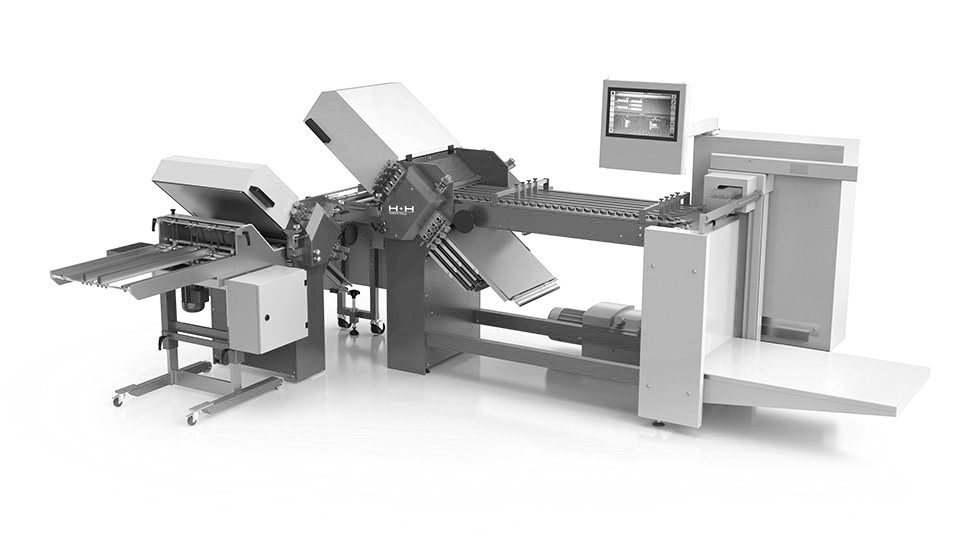

The Jack of All Trades for Package Inserts: The Folding Machine M9

The M9 is designed for the production of inserts for various fields, such as the pharmaceutical, cosmetics, food or agricultural industries. A further application is the production of multi-folded product information leaflets that can be enclosed with small electrical devices, for example. The M9 is available as a manual machine as standard. Optionally, the buckle plate and fold roller settings can be automated, resulting in a considerable reduction in set-up times. Recurring jobs can be easily called up from the machine control M1 Advanced.

- M1 Advanced machine control (MIS compatible)

- Saving of repeating jobs

- Extra long register table for perfect sheet alignment

- Ejection before the folding unit to avoid double sheets

- 10, 12, 16, 20 or 24 buckle plates

- Optional automated buckle plate and fold roller settings

- Ergonomic slitter shaft cassette with two slitter shaft pairs

- Transfer table with integrated ejection module for detected sheets

- Expandable with individual modules

Future-oriented technology: our additional folding machines

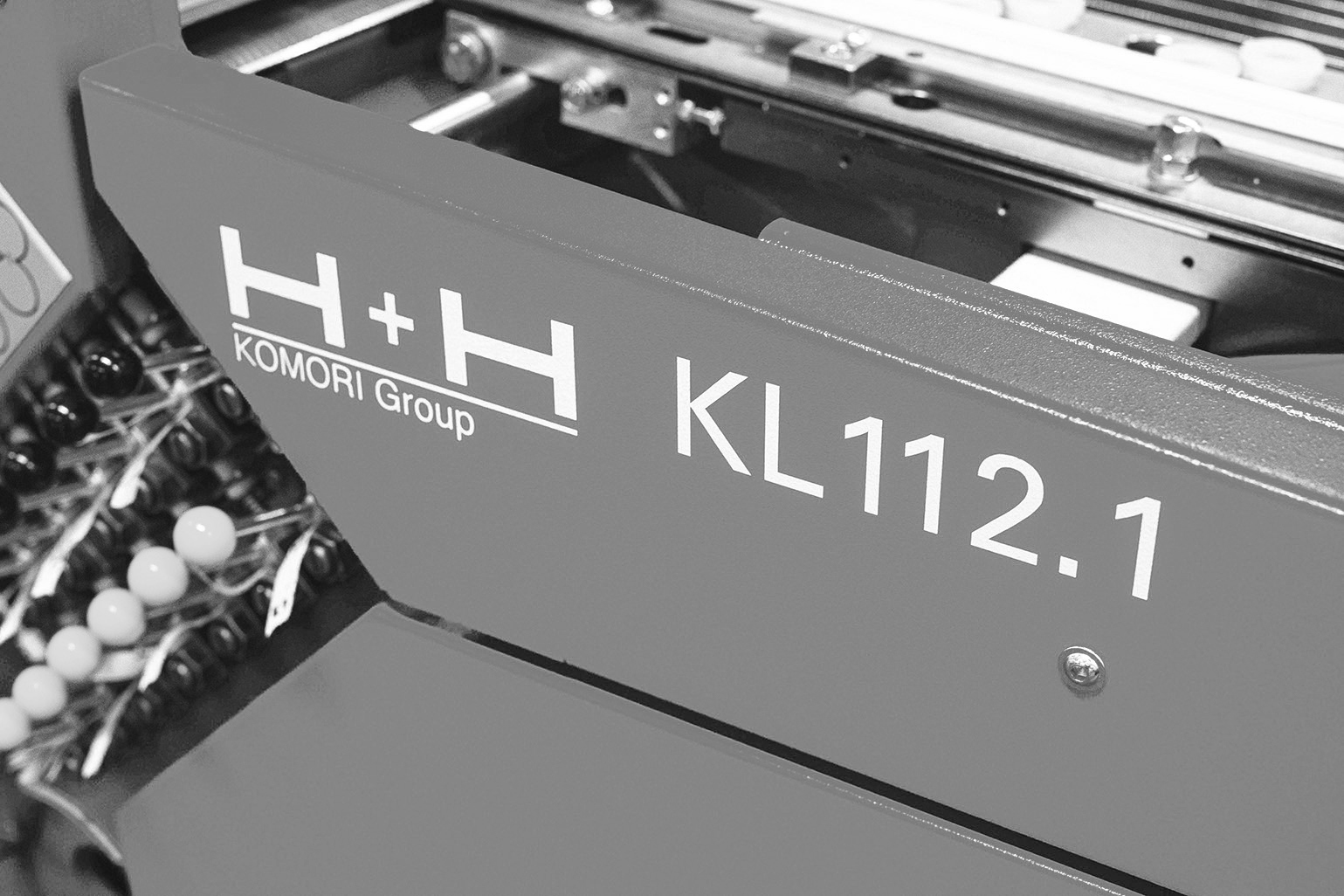

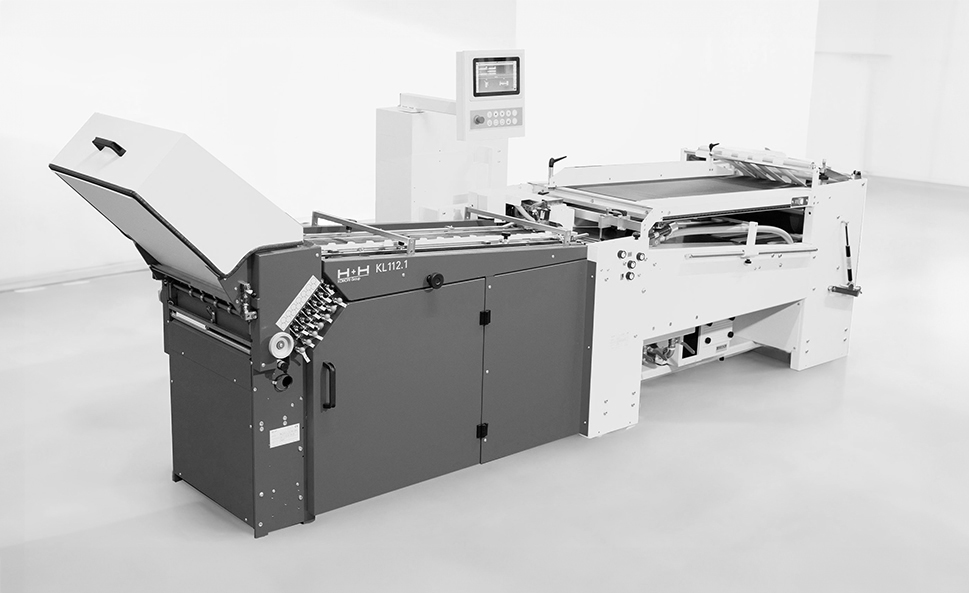

Mini folds, maxi efficiency: the compact folding machine KL112.1

The H+H smallest folding machine KL112.1 is designed for the production of small and smallest folded products. Due to the folding roller diameter of only 26 mm, a minimum fold length of up to 18 mm can be achieved. In conjunction with a maximum number of pockets of up to 24, large sheets can be folded down to a minimum final format.

The S45: Precise, Fast, and Flexible Folding

The small folding machine S45 is suitable for the production of short folded sheets. It is available in a predefined configuration. However, the choice of continuous- or flat pile feeder is available. By dispensing with machine variants, the S45 can be produced cheaply and quickly. The S45 package includes the feeder, the first and second folding units, the transfer unit, and the vertical delivery.