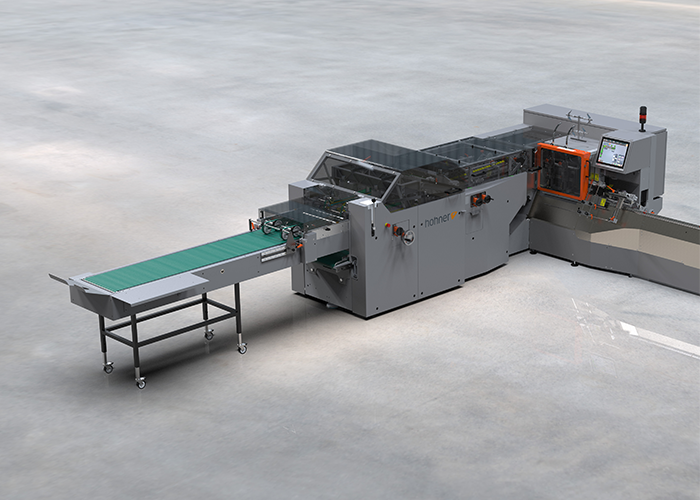

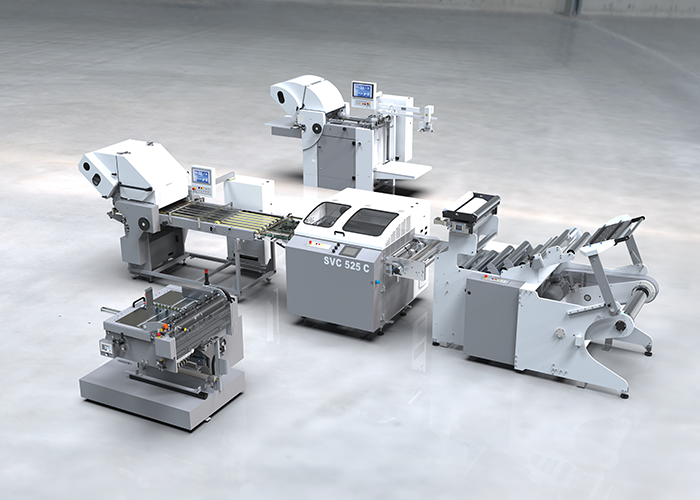

HHS-FUTURA

A puzzle like machine. As versatile as it gets.

HHS-FUTURA by Hohner is a modular, flexible, and economical solution for the sector of saddle stitching and digital processing. Due to its modular design, it can be individually tailored to meet specific needs. With more than 20 different configuration options that can even operate in parallel, HHS-FUTURA offers maximum versatility. In addition to its flexibility, the machine scores with its cost efficiency: It enables significant savings in energy costs, reduces the required floor space, and cuts the need for personnel in half. As an expert in the field of saddle stitching and as a market leader in the segment of stitching heads, Hohner incorporates extensive experience into the development of HHS-FUTURA. The hybrid saddle stitcher/DIGI-finisher concept is configurable and expandable in the long term, making it ideally suited to the trend towards smaller print runs and more individualized products.

- Modular Design: Individually customizable.

- Versatility: Over 20 configuration options, capable of parallel operation.

- Cost Efficiency: Savings in expenses, space & personnel.

- Expertise: developed by the global market leader in stitching heads.

- Long-term Flexibility: Expandable and configurable concept.

- Future-oriented: Meets the trend towards individual small batch production.

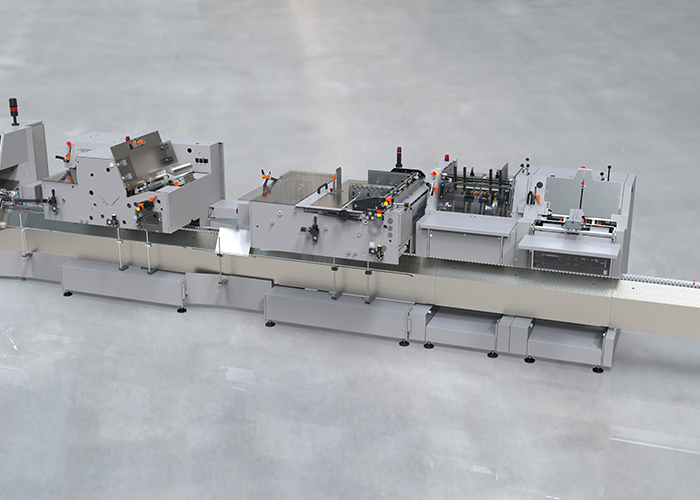

The puzzle pieces of HHS-FUTURA

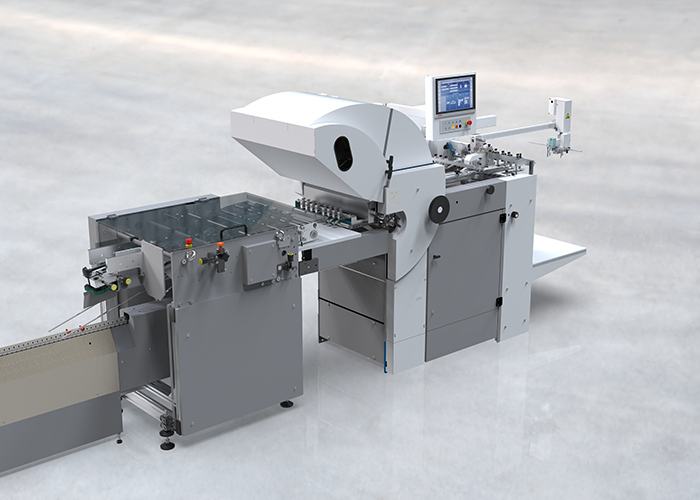

1. The solid base for HHS-FUTURA

A stitching unit with automated wire length and thickness adjustment including stitching leg via a 15 inch color touchscreen with intuitive and non text design and a trimmer allowing a format up to B4 final format with optimum trimming quality. Extremely user friendly.

2. Saddlestitcher with infinite modularity

Four different feeders to freely choose and combine:

3. Digital Finishing – From the roll or sheets.

With three different feeding systems, maximum flexibility is more than just a catchphrase.

The selection of components of these types from another manufacturer — with provided open interfaces — is also possible at any time.

4. Fold Stitcher

Extremely time-saving thanks to the integrated pre-process of folding for a sheet length of up to 1300 mm and a width of 520 mm (in the optional version, even up to 660 mm). Scoring and folding unit with a separate servo drive and positive-negative adjustability without the need for any tools.

5. Crossfolding Folding expert‘s K70 (MBO Postpress Solutions)

The K70 from MBO Postpress Solutions enables high-precision and high-performance production of folded products for medium and high print runs in a B1 format (70 x 100 cm), with direct delivery to a horizontal signature feeder.

6. Collating Towers – Nonstop Production inclusive.

The modular and flexible concept of HHS-FUTURA 9 also encompasses the Hohner-designed collating towers and a 90° delivery for the inline collating function. It is space-saving, compact, and designed for non-stop production.